Buy Baptistry Heater Heater Variants

NOT SUPPLIED WITH PLUGS, WIRING, CONTACTORS, ETC.

ALL WIRING TO BE CARRIED OUT LOCALLY BY A QUALIFIED ELECTRICIAN

WE RECOMMEND THAT RCBO’S (an RCD & an MCB combined) ARE FITTED ON ALL OPEN TANKS.

NEVER LET LIQUID LEVEL FALL BELOW TAPE MARKERS, SEE LAST IMAGE.

Call Jamie on 01827 215684 to discuss your Baptistry Heater needs.

While not strictly speaking designed to be a Baptistry Heater, our stock vat heater works with a bit of creativity, and is a good deal cheaper than Kosher ones available Here & Here.

Mr Roger Webb of the Christadelphian Church has shown great Creative spirit in using our £244.30 SS 3kW unit to baptise their growing flock.

If you calculate your Baptismal Font capacity, use our Water Heating Calculator, you shouldn’t need a Stat to control the temperature.

Just fill it up, activate the heater in, leave it on for X hours to get the water up to your desired temperature, then baptise away without freezing anyone to death!

Wim Hoff may feel this all a tad unnecessary?!? But each to their own.

The key thing to remember is that the first 12″ of the drop are cold & OK out of water.

THE REST OF THE DROP IS HOT & IS NOT OK OUT OF WATER.

It is a fire hazard, it will glow, it will go BANG!

So be creative, like Roger & cover all bases.

Our heaters feature:

- Heavy Duty Moulded ABS Terminal Box. 3ph – 300x100x100mm, single phase 100x100x100mm.

- IP54 rated Terminal box – suitable for outdoor use,

- 12.7mm or 1/2″ elements.

- Moulded cable entry glands.

- Removeable cover for easy access to wiring.

- Adjustable moulded mounting blocks.

- Cold section markings for visual prevention of liquid level drop.

- Robust construction.

Over the Side Vat Heater Sheath materials available include:

Pros & Cons

As with everything in life, it is all about the compromise. Over the side vat heaters have advantages over through the side heaters, but also there are downsides to be considered too.

Advantages

The main benefit to putting your heat in through over the side heaters is that the tank does not have to be drained in order to switch out a dead heater for a new one. As most “through the side” immersion heaters are located at the bottom of the vessel, as heat rises, so the vessel will have to be all but completely drained to change a screw in heater. Also, this “whip ’em out” flexibility allows these vat heaters to be used in multiple vessels. As long as they are switched off & allowed to cool before relocating, mind you! That school boy error will prove expensive, indeed.

Disadvantages

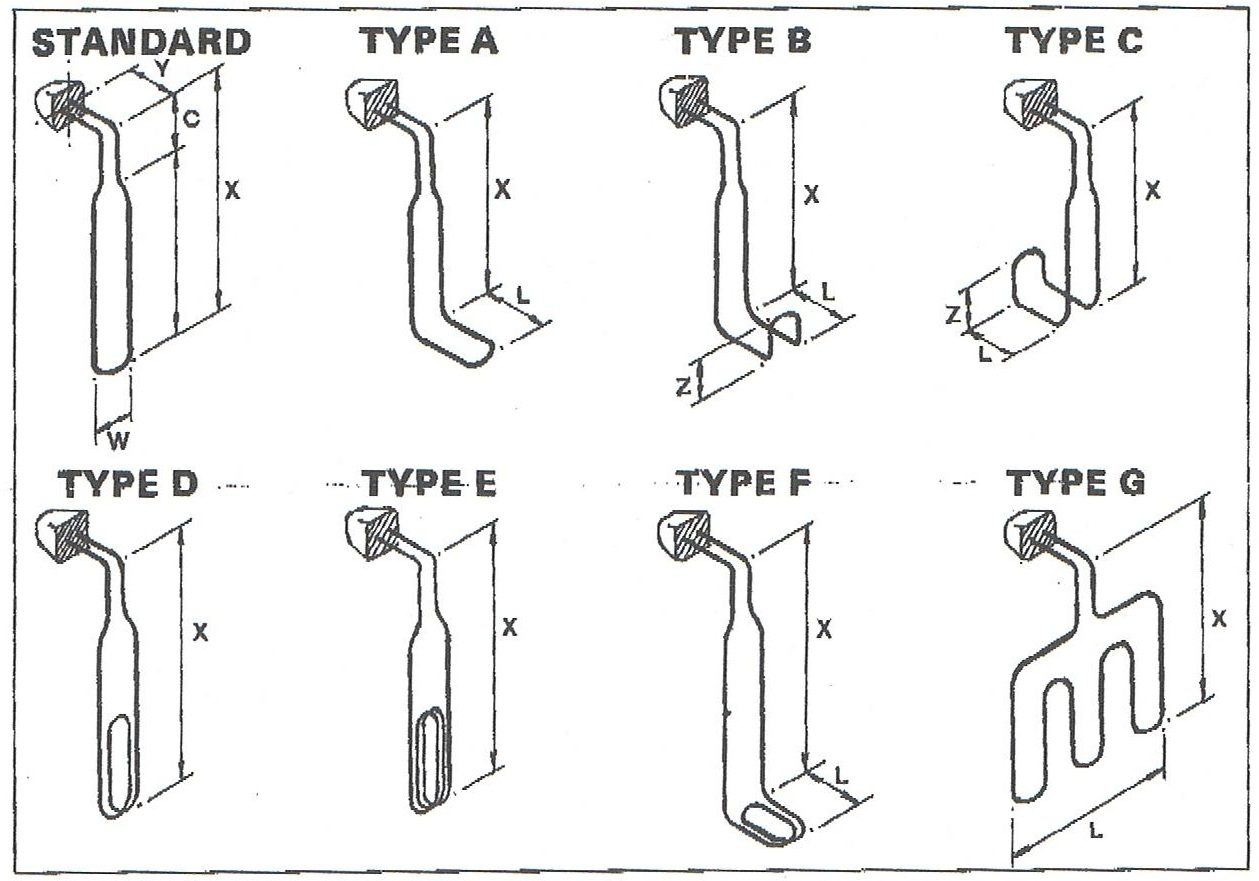

The downside to applying heat at the top of the vessel will become clear if your liquid level drops. If hot element is exposed to air, it rapidly becomes a fire hazard. And It will go BANG sooner rather than later. Thus, the default arrangement of 6″ on the horizontal (Y in the schematic above) gives you 12″ to play with, Matron! Therefore, we can lose the horizontal to give you 18″ of room for level drop. But the downside to this is that the terminal box must be suspended over the solution, both exposed to rising vapours and in danger of dropping into solution. Which will not end well, hence the recommendation at the top of the page.

Additionally, the cost of a Vat Heater Thermostat is another unfortunate downside, at the same cost as a single phase heater! An immersion heater, fitted thru the side of the vessel, comes with a stat pocket. Thus a bargain £30 stat can be added. Albeit a somewhat “Agricultural” one, with a variance of circa +/-7°c. This suits most customers, but if half a degree accuracy is required, a PID Controller will have to be fitted. This could be achieved in a vat stat, but as it is an entirely different & seperate housing, the cost is horrible at £200+, irrespective of SS, Titanium or PTFE.