Thank you Heather.

“Logitech is a world leader in materials processing, shaping, and surface finishing technologies. We specialize in the design and manufacture of precision lapping & polishing, chemical or chemical-mechanical polishing, cutting, and bonding equipment. Our adaptable system solutions are aimed at applications with the need for high specification surface finishes, prepared with the most precise geometric accuracy.

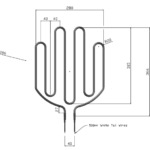

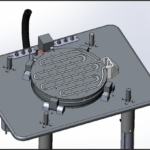

In 2022 a change was made to upgrade a range of our bonders to utilise heating element in a machined cavity rather than within a fully casted part. This was due to excessive lead times and suppliers less interested in Logitech’s smaller batch size requirements.

After a detailed development to achieve this new arrangement for the 12” Variant, we had placed an order with a Company in mainland Europe for a new heating element size. Due to misunderstanding, 8” elements, a previously-ordered size, were produced and not the 12” elements we ordered. Upon reorder it was found at this point that this error could not be rectified in time. Logitech were informed the manufacturing process which was used and technical difficulties meant this Company were not able to produce the requirements without lead-times exceeding contractual obligations to an important customer.

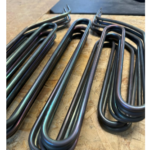

This is where UK-based IHUK Ltd were able to help. With the deadline for shipment being just over weeks away, a onversation on feasibility started off on a Friday. Jamie was right on-board to assist Logitech out of this situation, and made a solution a top priority. We were assured that IHUK could achieve a very tight deadline, and that they had a plan to achieve this goal.

An order was placed on the following Monday, along with sending a machined aluminium plate for use as a mould. On that Wednesday, Jamie at IHUK Ltd sent photos and videos of the production in process, with many of the elements already produced. By the Thursday the completed elements were delivered to Logitech, leaving more than a week to install these vital components and achieve our deadline. This exceeded our expectations, and was faster than Jamie’s own assurances of a tight lead-time.

IHUK were essential in helping Logitech complete the order for this upgraded bonder-saving a catastrophic breach of contract with an important customer- and have now built a continuing working relationship with Jamie and his team.”