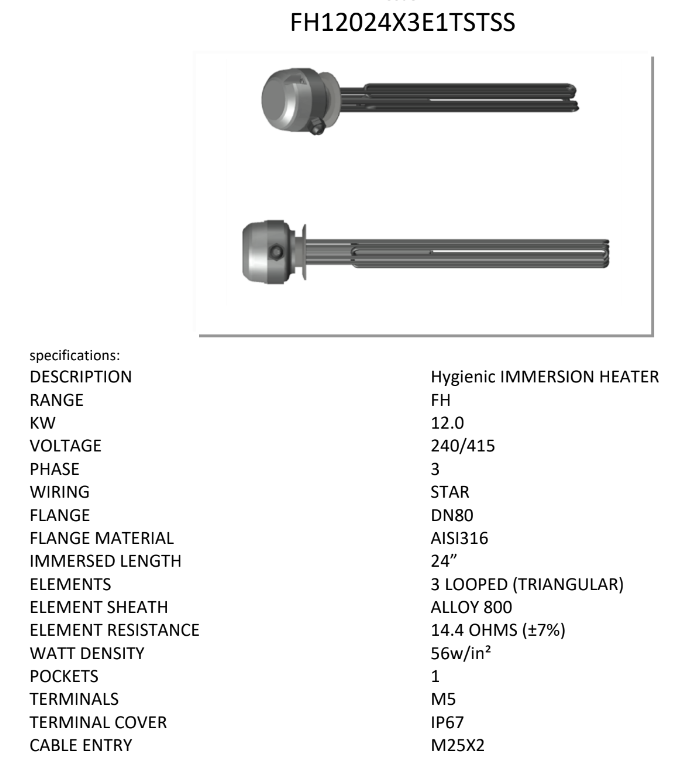

DIN or DN Flanged Immersion Heaters Images.

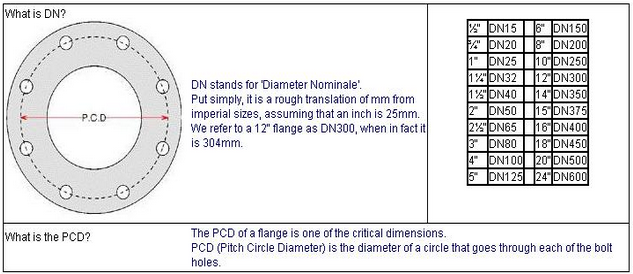

This table outlines the corresponding DN Imperial to Metric conversions and provides information on the Pitch Circumference Diameter of the bolt ring.

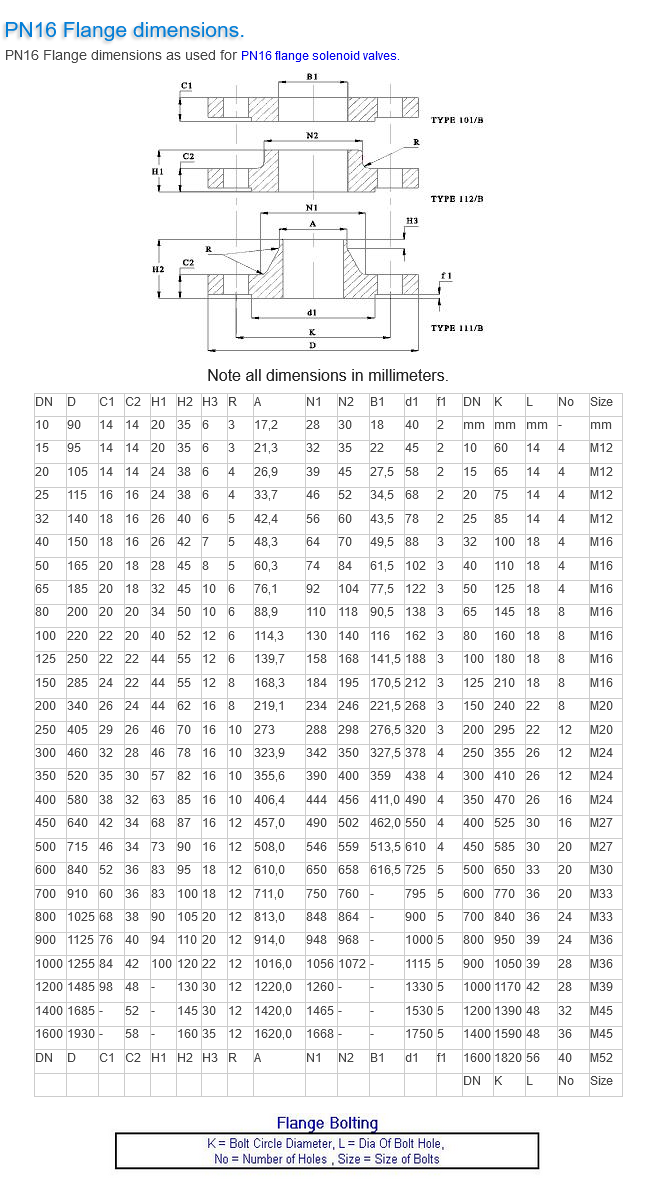

Specifically, it presents precise dimensions for various DN specifications, taking PN16 as an illustrative example.

As breweries (and distillers!) are our favourite customers, we tend to focus on the following 3 sizes, DN50 (3 U bent elements only). Through DN80 (sort of equivalent to the 2.25″BSP size prevalent in industry, so 3 looped elements potentially). Right up to DN125, (which could accommodate up to 9 U bent elements). These heaters are fitted with no screwing required.

As breweries (and distillers!) are our favourite customers, we like to make life easier for our friends who bring happiness & hangovers to us all. Removable Brewery Immersion Heater is a great solution if your budget allows.

A removable heater will allow essential cleaning to be conducted out of the vessel.

The “top hat” female tank ferrule allows the elements to be inserted directly & simply, with a high temperature gasket sitting between a similar “top hat” fixing on the heater.

This housing is all then held in place VERY tightly with a safety clamp. Using a wing nut for easier tightening.

This enables this heater to be rated up to 20 BAR of pressure. Far higher than a screwplug, at 6 BAR, should the need arise.

Bendy One For You, Sir?

This allows for elements to be curved in order to follow the circumference of the outside of the vessel, rather than going straight across the diameter. This greatly increases the amount of element we can squeeze into your vessel, which massively reduces the watt density of the elements. This is of particular benefit to brewers as your ingredients tend to stick to hot element. Like sh1t to a blanket.

Curved elements also lend themselves to a rolling boil, greatly favoured by some brewers. This rolls up the outside , then down in the middle, creating a vortex of sorts. If somebody wants to explain the benefits of that to me, I’m all ears.

It also allows for insertion to avoid any potential clashes with other fixings within the tank.

It would also lend itself to “splaying” the elements, once inserted, to provide greater gaps between the elements.

The potential downside is the physical space involved outside the tank to provide “wiggling in room”.

Plus all the other beneifits and features of our II Range (IP67 terminal box. INCOLOY® 800 sheathed elements) just tweaked.

The biggest benefit though is the ability to soak, powerwash, steam or scrub OUTSIDE of the vessel.

Now this is where the Heath Robinsin creative spirit of brewers can really come into play. We always had ideas about shiny stainless steel tubes, munsen ringed to a wall, to soak your heater in overnight for super easy cleaning. But no need, Niall at Third Barrel Brewing did it with a bit of toilet pipe and some gaffer tape, see images below.

More DIN or DN Flanged Immersion Heaters Images

Call Jamie on 01827 215684 to discuss your specific needs. Let’s collaborate.

*Formerly known as the “OH SHIT” Price. Mention this in your conversation & I’ll give you a discount for your diligence in actually checking the footnote. Fair play, to you!